-

-

Available Formats

- Options

- Availability

- Priced From ( in USD )

-

Available Formats

-

- Immediate download

- $179.00

- Add to Cart

-

- Printed Edition

- Ships in 1-2 business days

- $179.00

- Add to Cart

Customers Who Bought This Also Bought

-

API RP 1632 (R2010)

Priced From $73.00 -

NACE SP0296-2020

Priced From $179.00 -

NACE SP0472-2020

Priced From $179.00 -

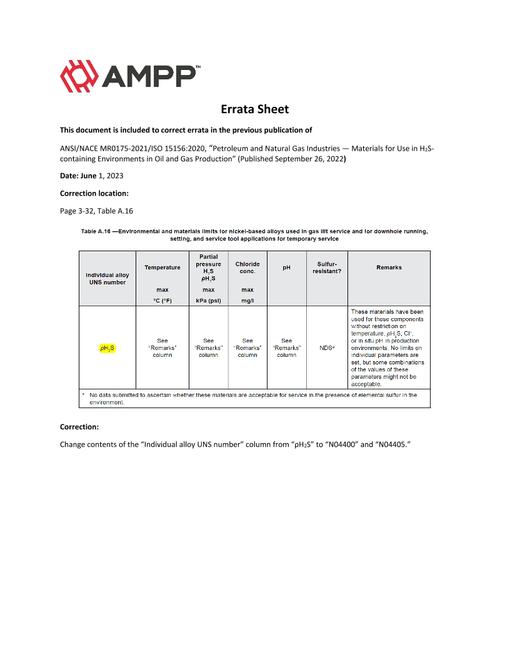

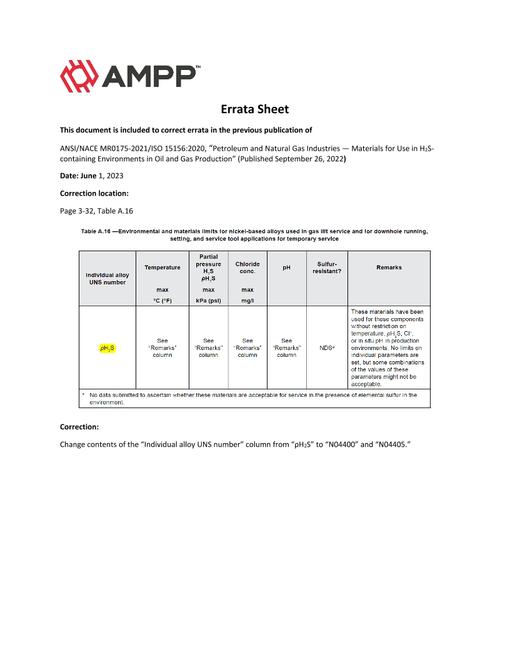

NACE MR0175-2021/ISO 15156-1:2020 & Technical Circulars 1...

Priced From $420.00

About This Item

Full Description

Examines varying procedures used by industry to protect austenitic stainless steel equipment while idle. Basic protection methods include nitrogen purging, alkaline wash solutions, and dry air purging. Protection of reactors is also addressed. Keywords: alkaline washing, austenitic stainless steels, nitrogen purging, polythionic acid, refinery equipment, stress corrosion cracking.

Document History

-

NACE SP0170-2018

Protection of Austenitic Stainless Steels and Other Austenitic Alloys from Polythionic Acid Stress Corrosion Cracking During a Shutdown of Refinery Equipment- Most Recent

-

NACE SP0170-2012

Protection of Austenitic Stainless Steels and Other Austenitic Alloys from Polythionic Acid Stress Corrosion Cracking During Shutdown of Refinery Equipment- Historical Version

-

NACE RP0170-2004

currently

viewing

Protection of Austenitic Stainless Steels and Other Austenitic Alloys from Polythionic Acid Stress Corrosion Cracking During Shutdown of Refinery Equipment- Historical Version

-

NACE RP0170-93(R1997)

Standard Recommended Practice - Protection of Austenitic Stainless Steels and Other Austenitic Alloys from Polythionic Acid Stress Corrosion Cracking During Shutdown of Refinery Equipment- Historical Version